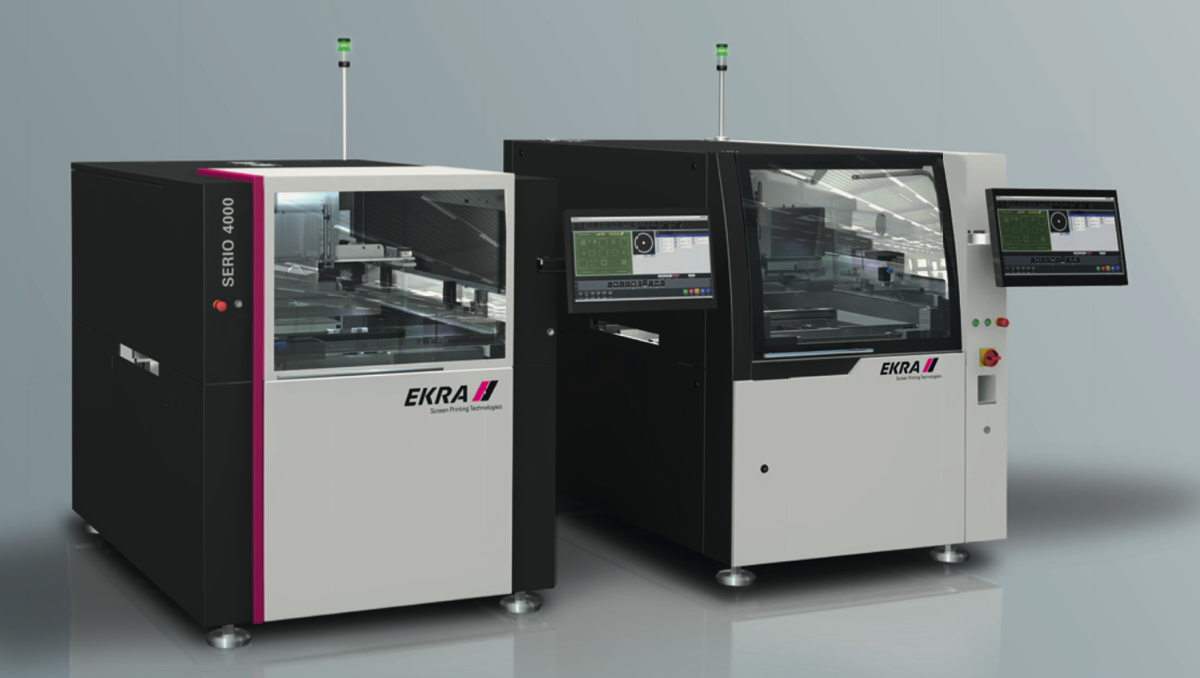

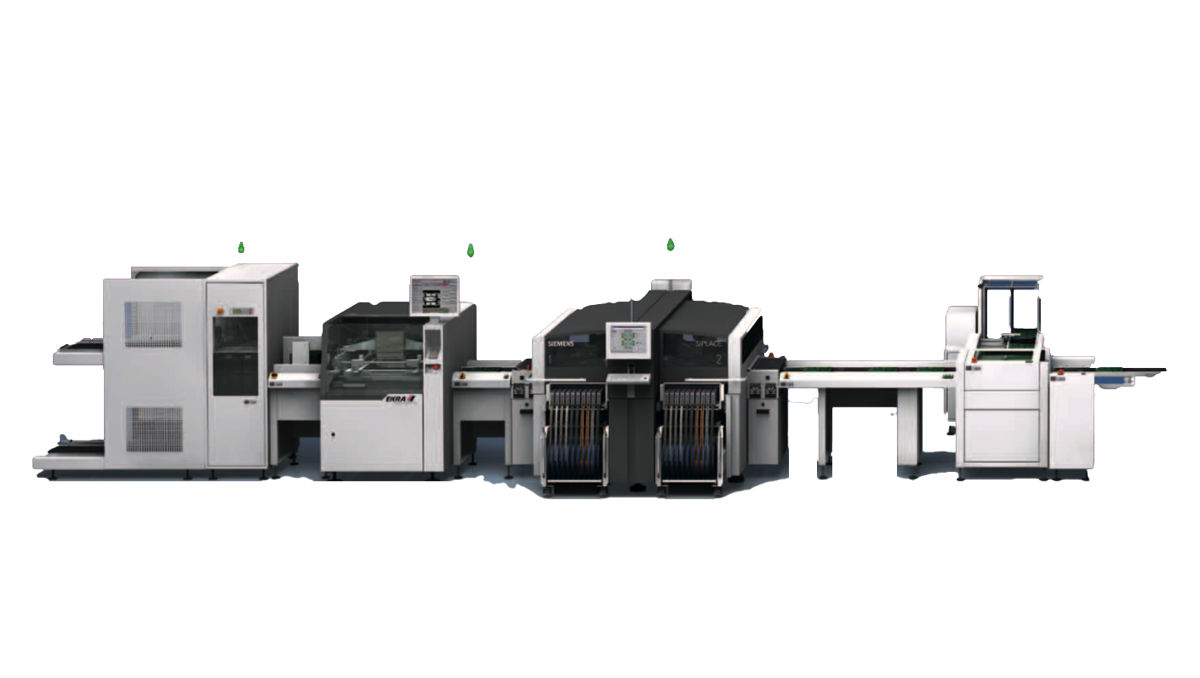

EKRA

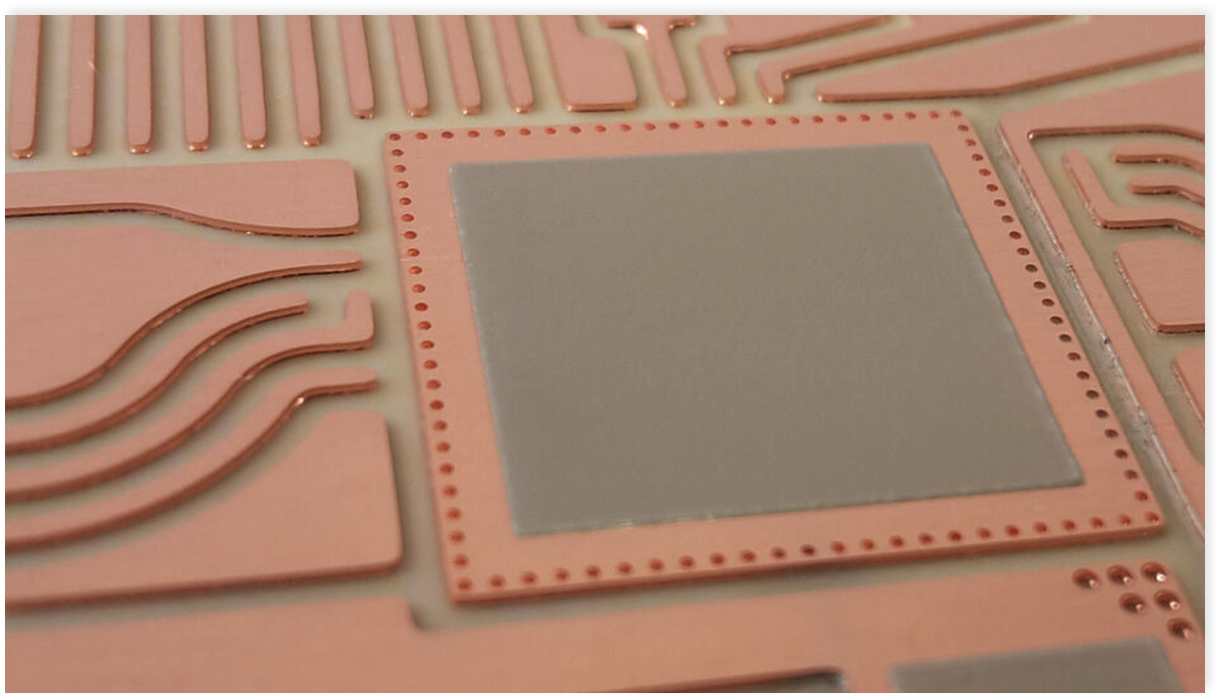

Printers: SMT • Semiconductor • Microelectronic • Thick Film • Long & Big Board

SERIO: Standard to High-End

HYCON: Special Solutions

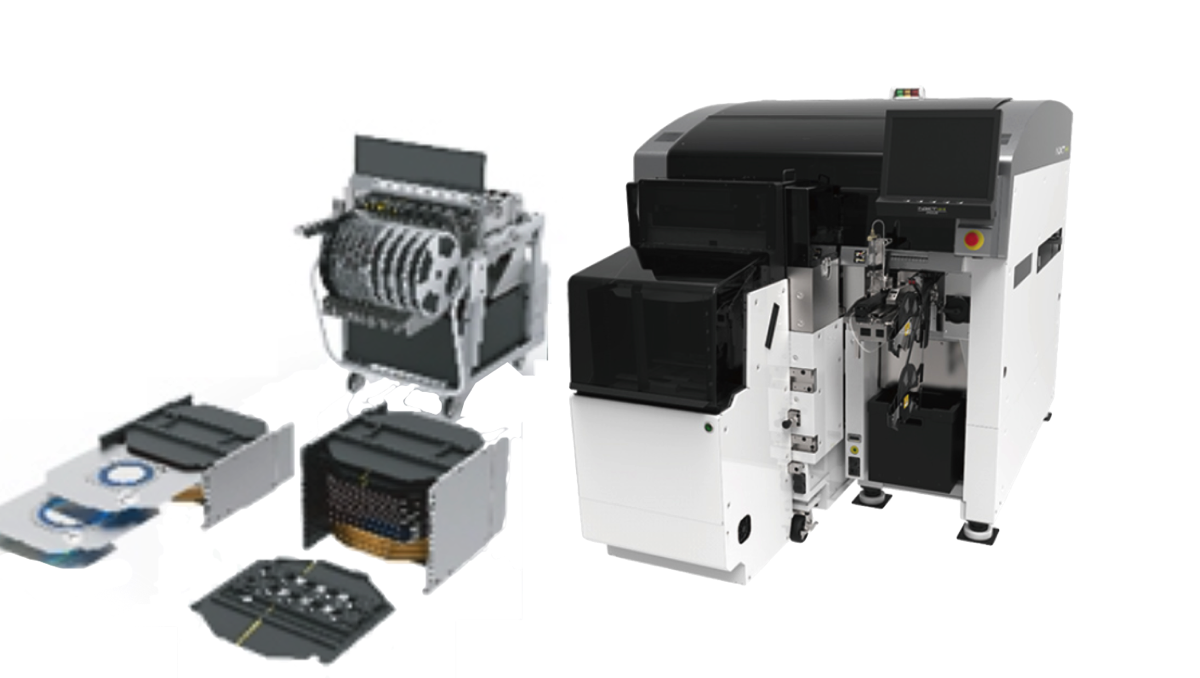

FUJI

Pick & Place for SMT, Semiconductor & Through Hole • Printers • SMD Storage Towers

NXT III: Scalable

sFab: Odd form, axial/radial

NXTR: Operator Free

GPX: Screen printer

AIMEX III: Flexible

sTower: Component Storage

NXT-H: Wafer, Die & SMD

Heller Industries

Reflow & Curing Ovens • Horizontal & Vertical • N2 • Fluxless Formic Acid • Vacuum & Pressure Processing

Reflow

Curing

Nordson Test & Inspection

YESTech & Cyberoptics AOI • SPI • ACI • Metrology

Automated Optical Inspection

Solder Paste Inspection

Microelectronic

Conformal Coat Inspection

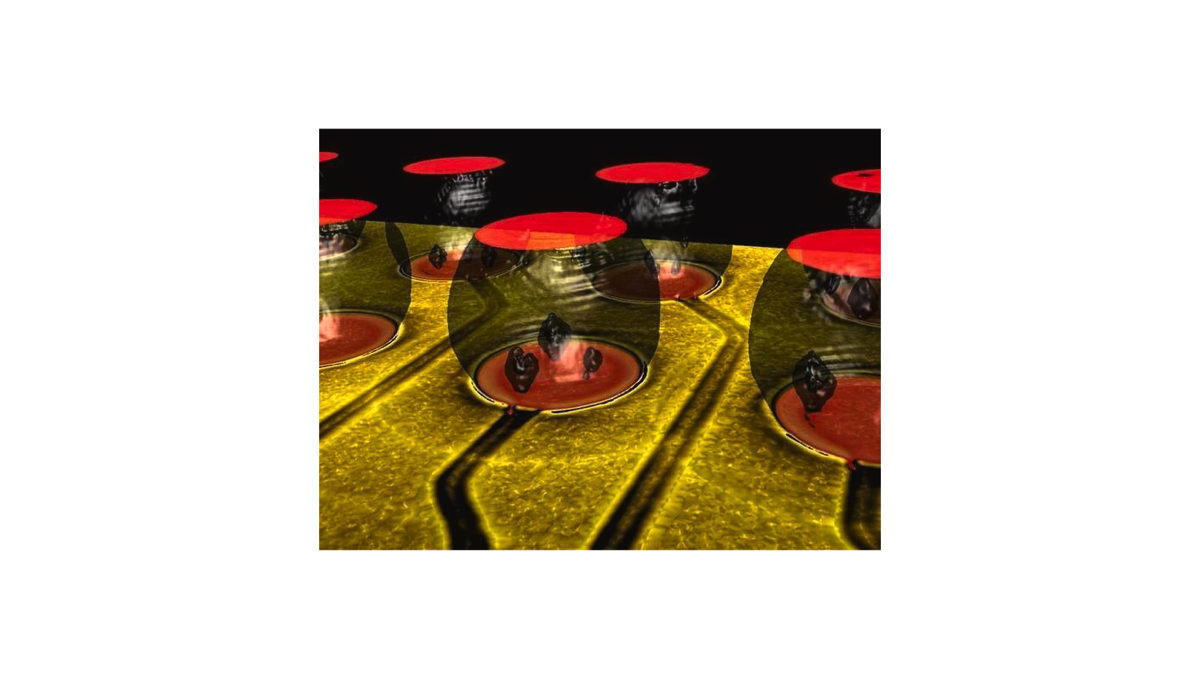

Dage High Resolution X-Ray Inspection (MXI)

Quadra MXI

CT Reconstruction

Matrix Automated X-Ray Inspection (AXI

In-Line AXI

Stand Alone AXI

Dage Automated X-Ray Component Counting

Component Counter

Nordson Electronic Solutions

Asymtek Precision Dispensing

Vantage

Forte

Quantum

Spectrum

Asymtek Conformal Coating

Select Coat Systems

Curing

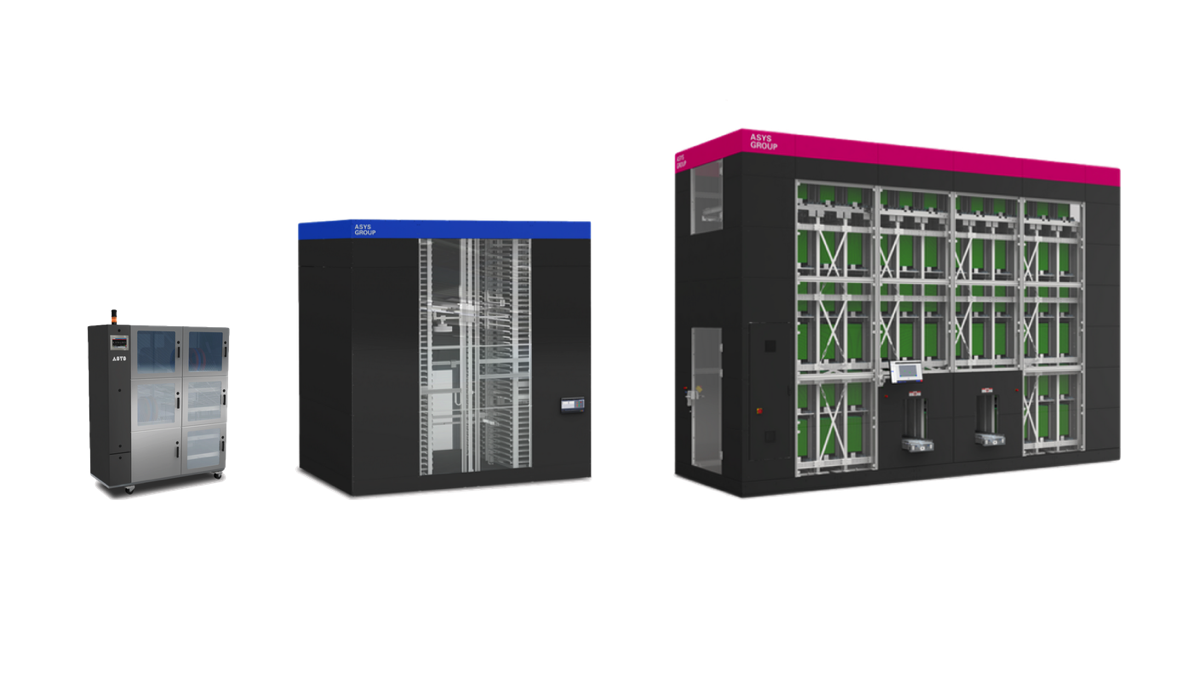

ASYS

PCB Handling Conveyors • Depanel/Route • Laser Mark/Label • Component Storage • Clean Room

PCB Handling

De-Panel

Marking

Material Storage

Takaya

Flying Probe Circuit Board Testers

Flying Probes

Aqua Klean Systems

In-Line Aqueous Cleaners • Closed Loop Systems

Typhoon Water Cleaners

Water Treatment

Austin America Technologies

Batch Cleaners • Stencil Cleaners • Solvent Cleaners • Ionographs

Aqua Rose Batch Cleaner

X-Series Stencil Cleaner

Mega Solvent Cleaner

Ionograph

Aegis Industrial Software

Software for Manufacturing Operations • Industry 4.0 • MES/MOM • NPI • Track • Trace • Report

MES

Industry 4.0

Reporting

Paperless Manufacturing