Competitive Edge Manufacturing Equipment

Founded in 1997, Competitive Edge Manufacturing Equipment (CEME) provides world-class automated electronic PCB assembly, inspection and test equipment for the Southern California, Southern Nevada and Baja California regions. For Baja California inquiries please visit www.ceme.mx.

CEME has provided automated surface mount assembly equipment and software solutions to over 350 companies ranging from Tier 4 owner/operator EMS providers to Fortune 500 EMS and OEM companies, including: Benchmark, NEOTech, Express Manufacturing, Northrop, SpaceX, General Atomics, Raytheon, Skyworks, Qualcomm, etc. No client is too small or too large.

CEME has provided automated surface mount assembly equipment and software solutions to over 350 companies ranging from Tier 4 owner/operator EMS providers to Fortune 500 EMS and OEM companies, including: Benchmark, NEOTech, Express Manufacturing, Northrop, SpaceX, General Atomics, Raytheon, Skyworks, Qualcomm, etc. No client is too small or too large.

Assembly Solutions

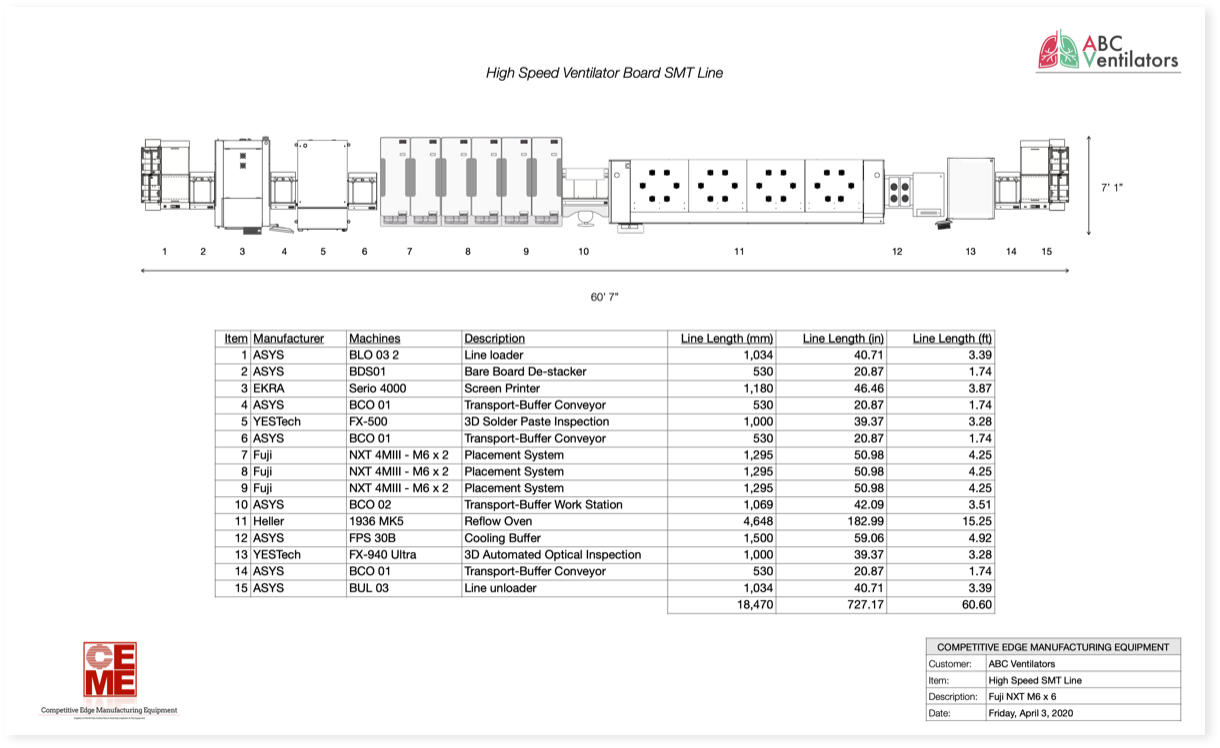

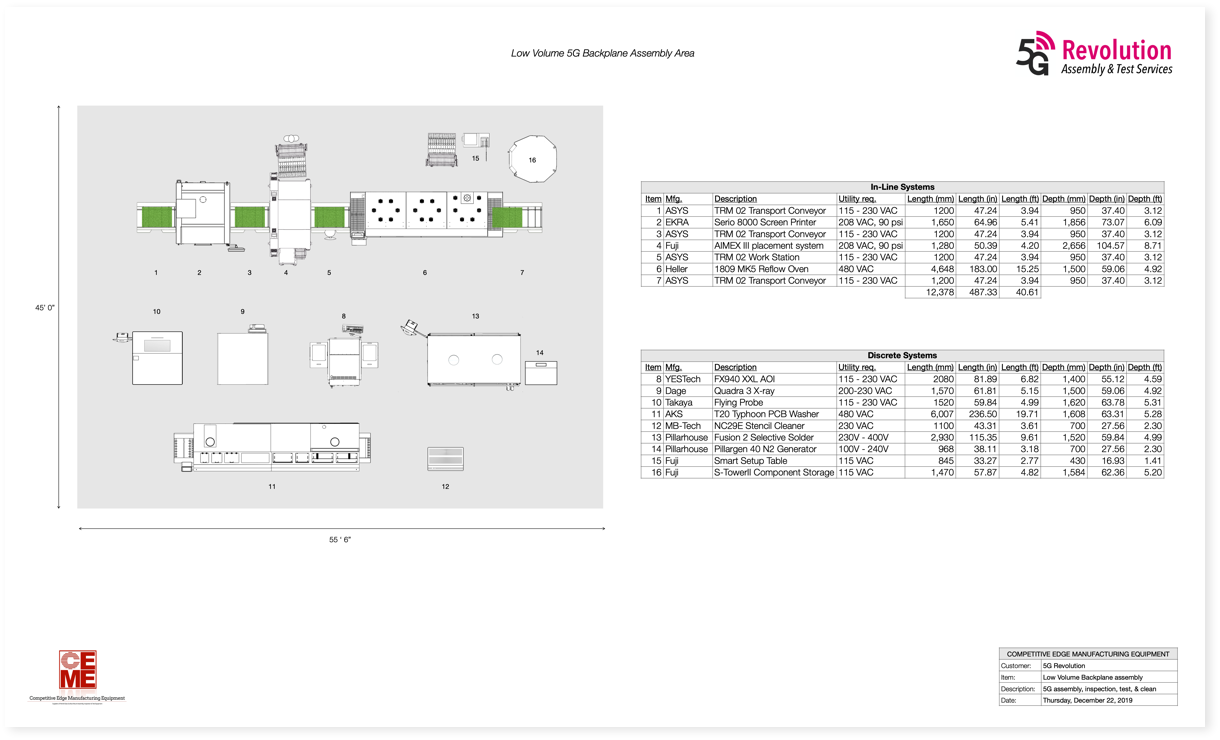

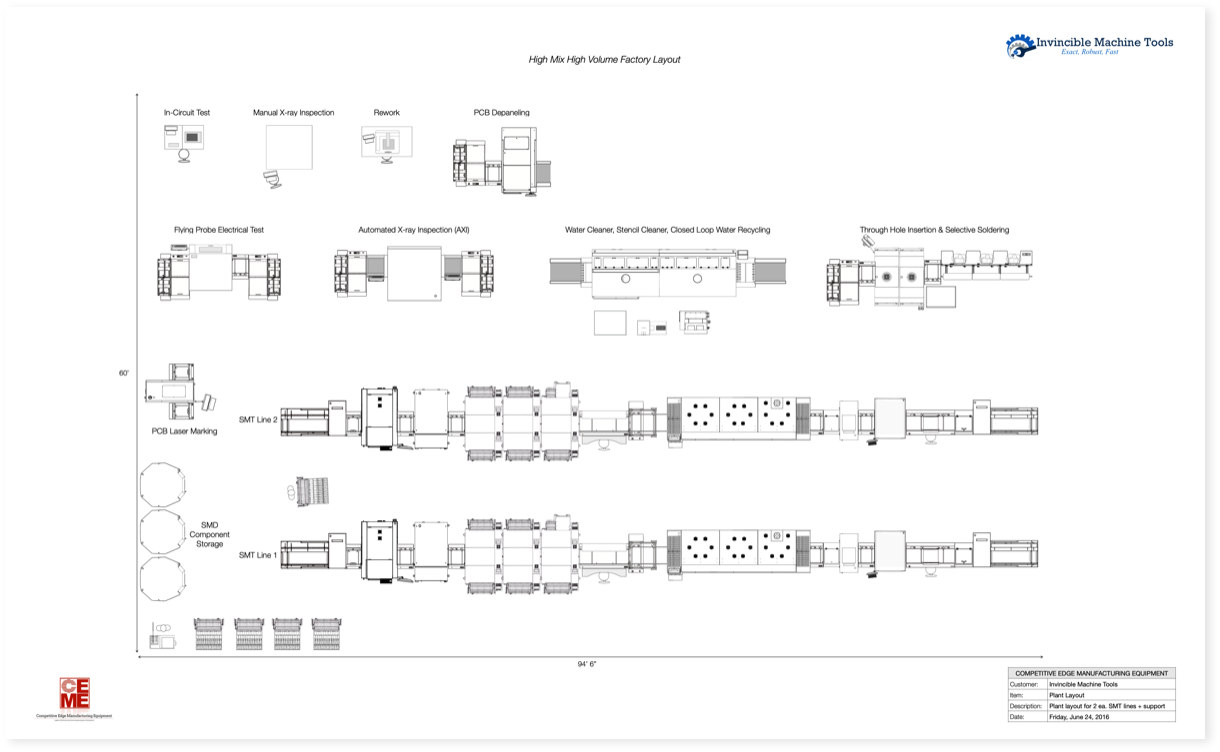

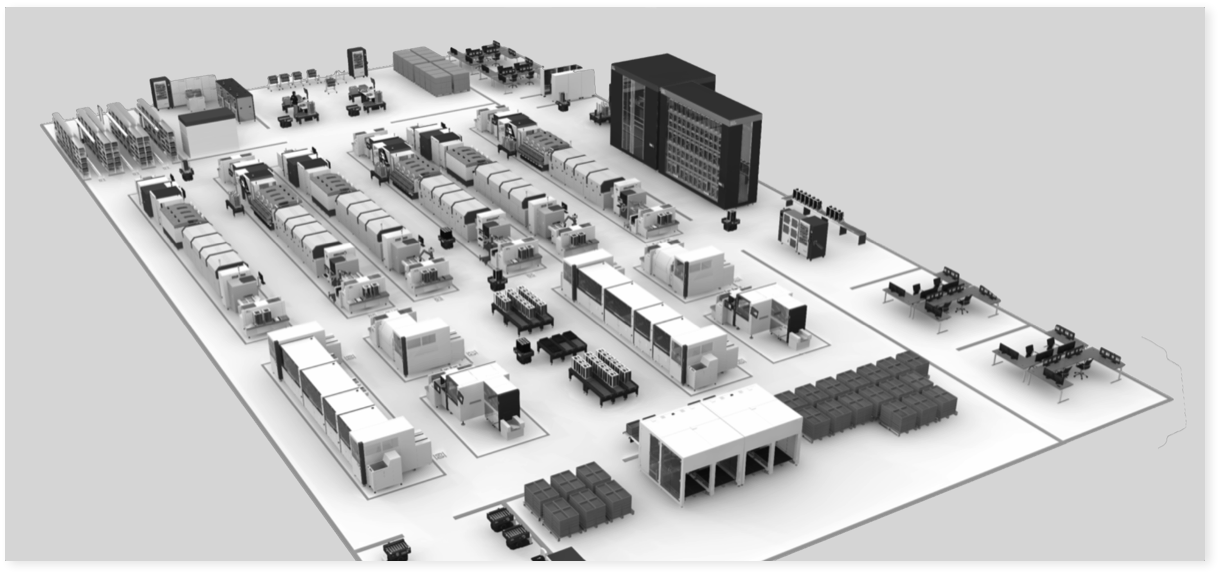

CEME offers fully integrated electronic and micro-electronic assembly line solutions as well as single pieces of equipment from original equipment manufacturers. Assembly, inspection and test equipment capabilities range from low-volume high-mix solutions to high-volume low-mix equipment configurations capable of meeting 150,000+ CPH per line throughput.

New low-volume Print-Place-Reflow SMT Lines can be purchased for less than $250,000. We also offer Remanufactured and Preowned Equipment. If leasing or special purchase terms are required we work with our suppliers and lease partners to provide cost effective solutions.

New low-volume Print-Place-Reflow SMT Lines can be purchased for less than $250,000. We also offer Remanufactured and Preowned Equipment. If leasing or special purchase terms are required we work with our suppliers and lease partners to provide cost effective solutions.

Electronic Assembly Equipment

The CEME product offering is anchored by World Market Share Leaders Fuji, Heller Industries The Nordson Group (Asymtek, YESTech, Dage, Matrix) and Takaya plus technology leaders ASYS/EKRA, Pillarhouse, Aqua Klean Systems and Aegis Software. Products include:

- Screen and stencil printers for solder paste and adhesives application

- Solder Paste Inspection (SPI)

- SMT component placement (Pick & Place)

- Through hole & odd form component placement

- Reflow and Curing ovens, convection, IR and UV technologies

- Automated Optical Inspection (AOI)

- Automated X-ray Inspection (AXI)

- X-ray inspection (MXI)

- Flying Probe and In-Circuit Testers

- De-paneling, router bit and laser based

- PCB Marking, labels and laser

- In-line and batch water cleaners with closed loop water recycling

- Component storage, automated and manual retrieval (SMD Towers & Material Warehouse)

- Component counting and counterfeit verification systems

- Conveyors and material handling systems

- MES/DPM/DFM Software - Automated assembly machine programming software